Textile coating

specialists

Productive processes

Acrylic coating

It acts as a coating that makes fabrics resistant and waterproof.

Water-repellent, Fire retardant, Anti-stain, Antibacterial (KEEP SAVE)

They are additives applicable by bath for the different properties required from fabrics, such as repellency and resistance to stains, fire retardant, anti-mite and antibacterial.

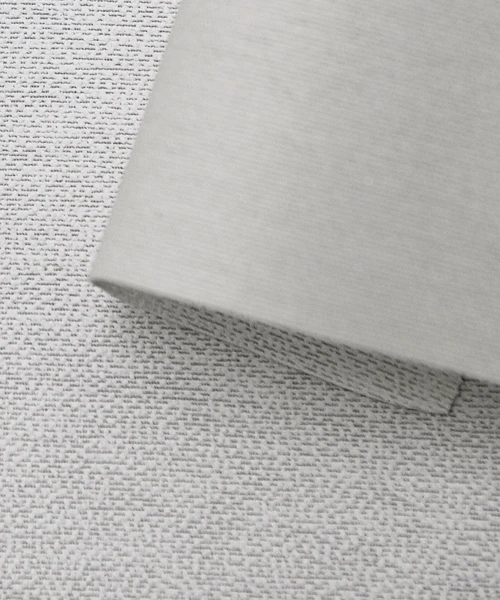

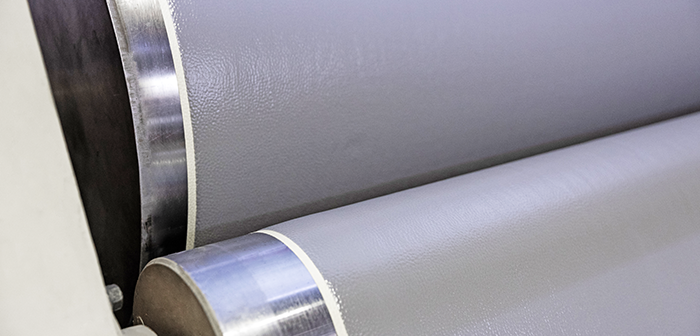

Lamination

By gluing a sheet with a fabric, it provides impermeability.

PVC Foam

In order to foam PVC, we use a 100 meter long continuous production line, allowing us to obtain a progressive and very regular emulsion that offers textiles a specific thickness.

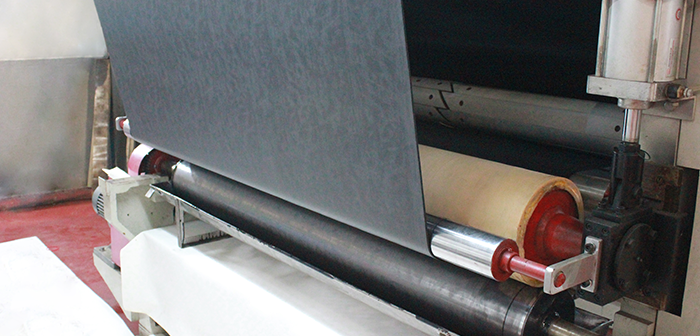

PU/PVC transparent coating

Emulsion plastificate with 3 in-line scrapers gives us the possibility of combining the different materials in PVC and PU, giving rise to articles such as synthetic leather, transparent lamination, mattress protectors, technical fabric such as labels for fabric, etc…

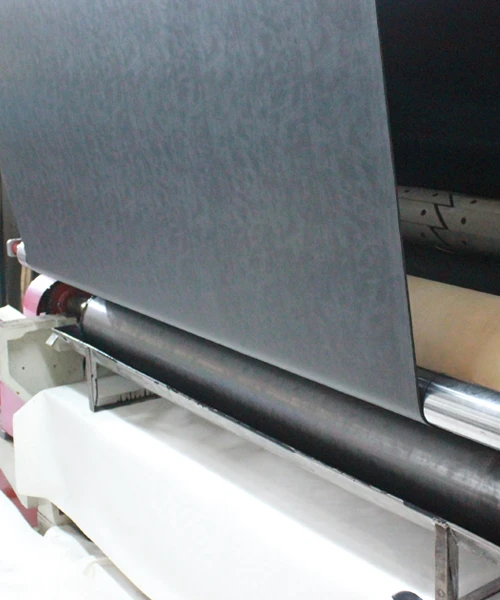

Anti-slip

The anti-slip coating process, applied through a micro-perforated cylinder, provides high anti-slip fixation.

Lacquered

Using the lacquer technique, it is possible to provide an extra degree of protection, as well as special gloss effects and a special texture to the touch, especially in materials such as synthetic leathers. Using machines with special cylinders that provide the fabric with a specially formulated lacquer to create this type of effects.

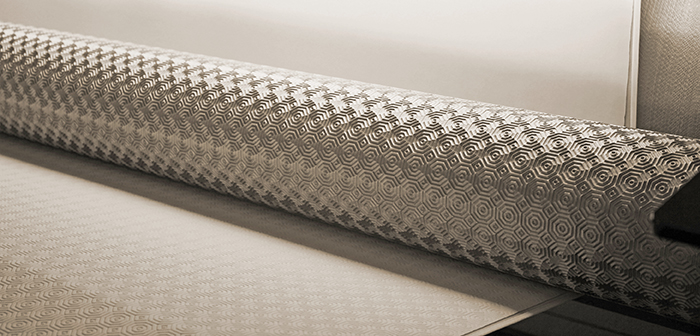

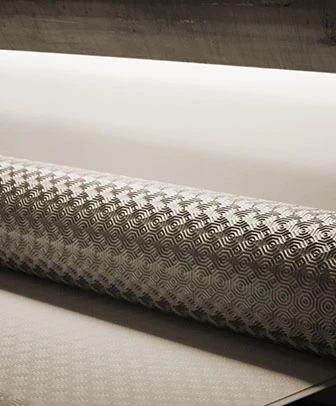

Embossed process

The embossed process consists of applying motifs and drawings to the fabric using cylinders with a certain pressure and temperature, creating a relief that in this case. It is fully customizable to the client’s tastes.